There are two methods for making instant coffee: Spray-Dried and Freeze-Dried.

For the first one, liquid coffee is sprayed in a fine mist through very hot and very dry air. By the time the coffee droplets land, they have dried into a fine powder.

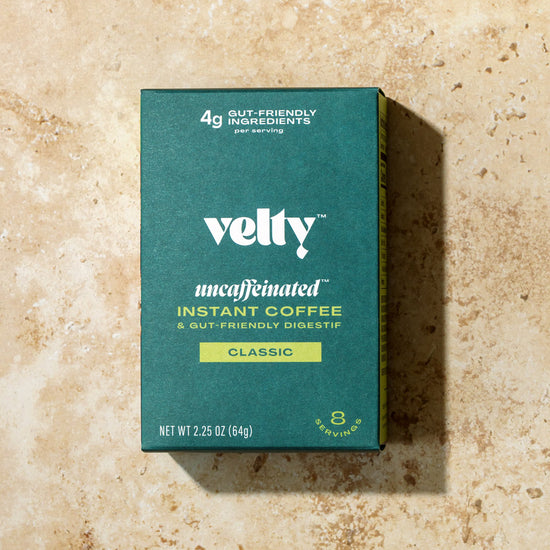

The second method is freeze-drying, which is the one that Velty will utilize for the decaf instant coffee in all of our blends. For this process, the water content is removed (dehydration) in order to preserve perishable materials, with the goal of extending their shelf life/durability. In our case, we remove water from a brewed coffee concentrate. Then, it is freeze-dried, which works by freezing the material (liquid), then reducing the pressure and adding heat to allow the frozen water in the material to change directly to a vapor (sublimate).

To effectively freeze dry, the coffee must remain under a certain vacuum pressure and temperature so that it doesn't melt and rapidly boil, exploding sticky coffee sadness all over the freeze drying chamber. It is not a surprise that with this type of care, freeze-dried coffee is typically very smooth with a medium to low acidity and bitterness. Though it may not completely replace your favorite brew method or cafe, instant coffee is very tasty and convenient when you just need something on the go.

Moreover, freeze drying - like coffee, is often considered to be both an art and a science because you can study it and eliminate variables in the process but even when you think you have it all figured out, it's never as repeatable as it looks on paper. It is a highly specialized process that requires constant management and adaptation.

Commodity instant coffees and boiled and separated from their aromatics, boiled again and reconstituted with their own aromatic extract and then sprayed into a hot room to boil of the last bit of water. This leaves you with what you would expect - a nasty, over-extracted, tanic, bitter, awful, harsh, astringent cup of coffee with little to no good flavor and even less aromatic quality. Freeze dried coffees are also often processed this way but leave out the spray drying process either completely or in part. Specialty instant coffee companies gently and evenly extract the coffee without aggressive boiling temperatures and then freeze dry to preserve those precious aromatics and flavors we all love from our favorite coffees

Freeze Drying Coffee In Simple Language

- Freeze drying unlike dehydrating and spray drying employs small amounts of heat under vacuum to achieve dehydration. The coffee is chilled to at least -40 (Celsius and Fahrenheit) so that when heat is applied the product doesn't melt back to liquid state.

- Vacuum is used because it lowers the boiling temperature of water to room temperature so that instead of melting back into liquid form the water turns straight into its gaseous state where it is collected by the condenser and refrozen away from the product until the process is complete.

- To effectively freeze dry, the coffee must remain under a certain vacuum pressure and temperature so that it doesn't melt and rapidly boil, exploding sticky coffee sadness all over the freeze drying chamber

Freeze Dried Coffee In Your Cup

More specifically, we at Velty, partner with Hasty Coffee, an instant coffee manufacturing company that has a proprietary multi-stage process that allows them to extract the coffee concentrate evenly without harsh temperatures or pressure. They freeze dry in small batches to obtain better control and preserve the original flavor and aromatics of each coffee utilized.

The freeze drying process takes place in the next three phases:

- Freezing

- Primary Drying (Sublimation)

- Secondary Drying (Adsorption)

Freezing Phase:

Freezing is the most critical phase of freeze drying, and there are many methods for it. Freezing can be done in a freezer, a chilled bath (shell freezer) or on a shelf in the freeze dryer (our method). Cooling the material below its triple point ensures that sublimation, rather than melting, will occur. This preserves its physical form.

Freeze drying is easiest to accomplish using large ice crystals, which can be produced by slow freezing or annealing. However, with biological materials, when crystals are too large they may break the cell walls, and that leads to less-than-ideal freeze drying results. To prevent this, the freezing is done rapidly. For materials that tend to precipitate, annealing can be used. This process involves fast freezing, then raising the product temperature to allow the crystals to grow.

Primary Drying (Sublimation) Phase:

Freeze drying’s second phase is primary drying (sublimation), in which the pressure is lowered and heat is added to the material in order for the water to sublimate. The vacuum speeds sublimation. The cold condenser provides a surface for the water vapor to adhere and solidify. The condenser also protects the vacuum pump from the water vapor. About 95% of the water in the material is removed in this phase. Primary drying can be a slow process. Too much heat can alter the structure of the material.

Secondary Drying (Adsorption) Phase:

Freeze drying’s final phase is secondary drying (adsorption), during which the ionically-bound water molecules are removed. By raising the temperature higher than in the primary drying phase, the bonds are broken between the material and the water molecules. Freeze dried materials retain a porous structure. After the freeze drying process is complete, the vacuum can be broken with an inert gas before the material is sealed. Most materials can be dried to 1-5% residual moisture.

If I could suggest anything - it would make the most sense to focus in more on why freeze drying matters for what you're going to taste in your cup. Then maybe have just a general point style description of the process and maybe follow the coffee through the freeze drying process.